.jpg) Featuring a revolutionary design and collet system, the Ultra-Lock Milling Chuck allows for high-speed applications up to 20,000rpm and offers incredible benefits compared to standard End Mill Holders such as high accuracy and higher rigidity.

Featuring a revolutionary design and collet system, the Ultra-Lock Milling Chuck allows for high-speed applications up to 20,000rpm and offers incredible benefits compared to standard End Mill Holders such as high accuracy and higher rigidity.

View all features and advantages

Features | Benefits |

| · invented by Nikken | > Nikken patented design (US 7018919) |

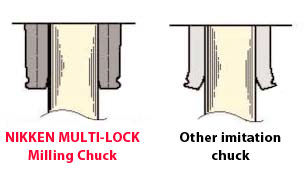

| · 140% more bearing surface than imitations | > more gripping power |

| · sub-zero treatment | > prevents deformation over time |

| · nose clamping & nut body contact | > higher runout accuracy |

| · thick body & internal slots | > strong chucking torque and rigidity |

| · quiet and stable heavy milling |

Milling Chuck vs End Mill Holders: learn why it's worth upgrading

| Milling Chuck | End Mill Holder | |

| Runout at 4x Diameter | 0.0002” | varies |

| Torque (1/2” shank) | 295 N.m | Breaking point |

| Chucking Capacity | 2” | 2” |

| Max. Speed(rpm) | up to 20,000 | up to 10,000 |

| Collet Style | Straight (KM) | n/a |

| Coolant Option | thru/jet/collet slots | jet slots |

| DIN option | yes | yes |

| 3-Lock option (Dual Contact Spindle) | yes | n/a |

| Noise harmonic vibration | low | medium |

| Taper size available | CAT40, 50, BT30, 40, 50, HSK63, 100 | CAT40, 50, BT30, 40, 50 HSK63, 100, 125 |

Even Gripping Along Entire Length of Cutter

Even Gripping Along Entire Length of Cutter

Clamping along the entire shank is a key condition for precise milling. Without this critical factor, surface finish, tool life, rigidity and runout accuracy will be jeopardized.

Only Nikken Milling Chuck clamps even at 3mm from the nose. This makes the Anniversary Type Milling Chuck ideal for roughing and finishing.

Strongest Mechanically Gripping Holder In The World!

Strongest Mechanically Gripping Holder In The World!

Internal slots together with thickened wall of the chuck body ensure no distortion even at heavy milling. Thus smooth milling work is achieved without the vibration or slipping of the end mill.

Solid one-piece body made of high strength Nickel Chromium Molybdenum 4340 Alloy.

Unique Sub-Zero Treatment (-90 deg. C)

Unique Sub-Zero Treatment (-90 deg. C)

All Nikken Milling Chucks are cryogenically treated after heat treatment to remove residual Austenite. This creates a uniform Martensite state and eliminates warpage and distortion, preventing deformation during the life of the toolholder.

Milling Chuck Collets

- KM collet: high precision reduction collets extends the chucking flexibility of the milling chuck

- NK collet: adjustable collet offering a built in back up screw for repeatability when replacing cutters

- CCK collet: coolant thru collet for high pressure coolant applications

- CCKN collet: adjustable coolant thru collet