Shrink Fit Units

Clearance

Shrink Fit Units for Shrink Fit Holders

Shrink fit units employ a process known as shrink fitting to tightly grip the tool inside the toolholder, ensuring stability and precision during machining operations. Here's a general overview of how shrink fit units typically work:

Heating: The toolholder is heated, usually through the use of an induction heating system, to a specific temperature. This heating causes the toolholder to expand slightly.

Tool Insertion: The cutting tool is then inserted into the heated toolholder. Because the holder is expanded, the tool can be easily inserted.

Cooling: Once the tool is inserted, the toolholder is allowed to cool. As it cools, it contracts, firmly gripping the tool with significant force due to the shrinkage of the metal.

The result of this shrink fitting process is a secure and precise toolholding solution that minimizes vibration, runout, and other issues commonly encountered in machining processes. Overall, shrink fit holders offer significant advantages in terms of toolholding strength, precision, and reliability, making them a preferred choice for many manufacturing applications, especially those requiring high-speed and high-precision machining.

Five Critical Features in Shrink Fit Units

Some key challenges manufacturers encounter when using some shrink fit technology is overheating the tool when using a manual control with a shrink fit unit, and then the toolholder loses its elasticity over time and no longer works properly. Another issue is having a tool break inside the shrink fit holder and not being able to get it out of the holder. Additionally, operating the shrink fit unit while the operator is trying to hold the heated toolholder in their hand at the same time can be a safety issue. Finally, if the shrink fit unit needs service or repair, sending the entire unit back will cause downtime.

Here are 5 critical features to look for in a shrink fit unit to overcome these issues and more:

Eliminate Overheating Toolholders - automatic detection of cutting tool sizes allows the toolholder to get the proper amount of heat for the proper amount of time which improves the longevity of the tool

Easily and Safely Remove Broken Tools - heat inductor can rotate 180 degrees to help safety remove broken cutting tools

Easily and Safely Remove Broken Tools - heat inductor can rotate 180 degrees to help safety remove broken cutting toolsSplit Ring Accommodates Lollipop Cutters - heat induction ring cut in half to use with a lollipop cutter

Foot Pedal for Safety - allows heating of tool while keeping both hands free to have more control to handle a heated toolholder

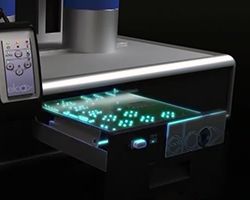

Minimize Downtime for Service and Repair - a slide out control module allows for quick replacement of electronic components

Minimize Downtime for Service and Repair - a slide out control module allows for quick replacement of electronic components

Watch the video to learn more:

Shrink Fit Unit Models

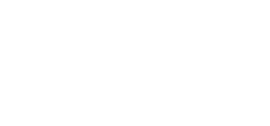

Lyndex-Nikken offers two shrink fit unit models: Start.2 is an entry level shrink fit unit that is compact and lightweight, and the FI-6 shrink fit unit is ideal for shops doing high changeovers for production setups. Both models feature:

- High speed shrinking for most shank sizes in 2 seconds

- Automatic detection of cutting tool sizes to eliminate overheating of the toolholder

- Inductor rotates 180° to easily remove broken tools

- Optional foot pedal allows heating of tool while keeping both hands free for safety and more control

- Shrink and unshrink any type of tools and cutters - tool shank must have h6 tolerance

- Adapters to accommodate multiple taper types (ISO, HSK, Polygonal)

- Widest shrinking range available for a desktop unit: 0.079” - 1.575” (Ø 2 – 40mm)

- Remote control pendant - shrink and cooling unit linked and controlled with one pendent

- 3-Phase power supply available in 200V or 400V – no transformer needed

- Unique slide-out control module for easy service or repair within 24 hours

Additional features specific to each model include:

Start.2 Shrink Fit Unit – with a compact and an ergonomic design, it is easy to operate. Features include:

Start.2 Shrink Fit Unit – with a compact and an ergonomic design, it is easy to operate. Features include:- Easy mobility due to compact size and lightweight materials

- Operate up to 2 cooling units simultaneously (2nd unit is an optional purchase)

- Maximum tool height: 12.4” (315mm)

- Shrink machine unit net weight: 41.9 lbs. (19 kg)

Watch the video to learn more about the Start.2 shrink fit unit:

If you have already purchased a Start.2 shrink fit unit and need to know how to set it up and use it, watch this video:

FI-6 Shrink Fit Unit - Built for high changeover demands, and designed with safety in mind. This robust shrink fit unit has one heating unit and two cooling towers combined into one unit. A moveable pot enables better safety so the operator does not have to touch the heated toolholder. Shrink fit unit features include:

FI-6 Shrink Fit Unit - Built for high changeover demands, and designed with safety in mind. This robust shrink fit unit has one heating unit and two cooling towers combined into one unit. A moveable pot enables better safety so the operator does not have to touch the heated toolholder. Shrink fit unit features include:- Two built in cooling units to support high quantity tool assembly - allows you to cool a toolholder while heating a second tool

- Maximum tool height 17” (432mm)

- Shrink machine unit net weight (options excluded): 143.3 lbs. (65 kg)

Watch video to learn more about the FI-6 shrink fit unit:

Videos: Why Manufacturers Choose Lyndex-Nikken Toolholders

Hear and see for yourself how Lyndex-Nikken quality toolholders provide optimal machining solutions for: