Live and Static Tools

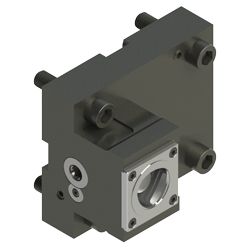

Clearance

Live and static tools help manufacturers overcome challenges related to productivity, complexity, accuracy, material waste, costs, and competitiveness, ultimately enabling them to produce high-quality parts efficiently and effectively.

Live Tools Enable Efficiency and Versatility

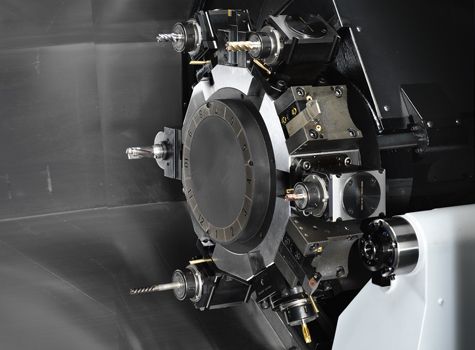

When a workpiece is held in position by the lathe and the cutting tool rotates to perform the machining process, the tooling is called a live tool. Live tools enable machining processes to be more efficient and versatile as they can perform multiple operations without the need for changing machines or repositioning of the workpiece. Parts can be machined on the main spindle or sub-spindle of the lathe.

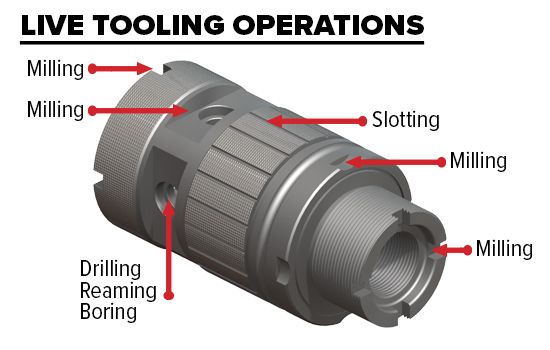

High Performance Live Tools Turn Lathes Into Milling Machines

Using live tools can turn your lathe into a milling machine to perform milling, drilling, reaming, boring, and slotting, etc.

Live Tool Interfaces for CNC Turning Centers, Lathes, and Mill-Turn Machines

Live Tools - PSC Polygonal: Provides increased stability and versatility in machining. PSC polygonal shank toolholders have a standardized interface as per ISO 26623 enabling extreme stability and a rigid connection between the tool and machine.

Live tools with PSC polygonal connections offer several advantages:

Reduced Setup & Tool Change Time: Enables reduced downtime and increased productivity, so maximum utilization of the machine especially for complex parts.

Increased Stability & Versatility: The secure connection ensures that the live tool remains stable during machining operations, reducing vibrations and improving surface finish on machined parts.

Compatibility: PSC polygonal connections are standardized, making them compatible with a wide range of CNC machining centers that support this type of interface.

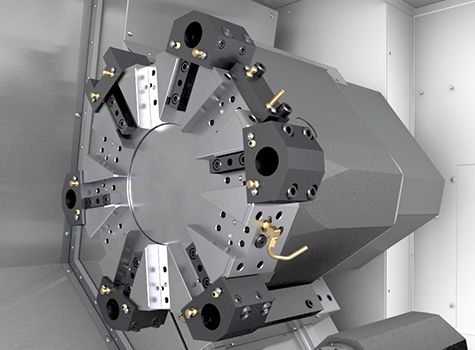

Live Tools - Bolt Mount: Used in machining centers, particularly in mill-turn machines or multi-tasking machines. These tools are designed to be mounted onto the machine's turret via bolts or screws enabling complex machining operations to be performed with precision and efficiency.

Bolt mount live tools offer several advantages:

Stability: Bolt-mounting ensures that the live tool is securely attached to the machine, minimizing vibrations and ensuring machining accuracy.

Versatility: These tools can perform a variety of machining operations such as milling, drilling, and tapping, etc. allowing for increased flexibility in part production.

Interchangeability: Bolt-mount live tools can be easily replaced or swapped out on the machine's turret, enabling efficient tool changes to accommodate different machining requirements.

Live Tools - VDI (Verein Deutscher Ingenieure or Association of German Engineers): A standardized interface system predominately used in Europe that allows for quick and precise tool changes on the tool turret of CNC lathes. It consists of a series of numbered tool stations arranged in a circular pattern on the turret. Each tool station is designed to hold a specific tool or tool holder. The standardized design ensures interchangeability of tooling across different machines and manufacturers that adhere to the VDI standard.

The VDI system for live tools offers several advantages, including:

Quick Tool Changes: The standardized interface allows operators to change tools rapidly, reducing setup time and increasing machine productivity.

Tool Repeatability: The precise design of VDI toolholders ensures repeatability in tool positioning, resulting in consistent machining accuracy.

Tool Flexibility: Different types of tools, such as turning tools, boring bars, drill holders, and live tools, can be mounted on the same turret, providing versatility in machining operations.

Modularity: VDI tooling systems often feature modular components, allowing for easy customization and adaptation to specific machining requirements.

Live Tools-Turret Specific: Offered for a multitude of machine builders to maximize the capabilities of each CNC machine equipped with turrets, offering increased flexibility, efficiency, and productivity in machining operations.

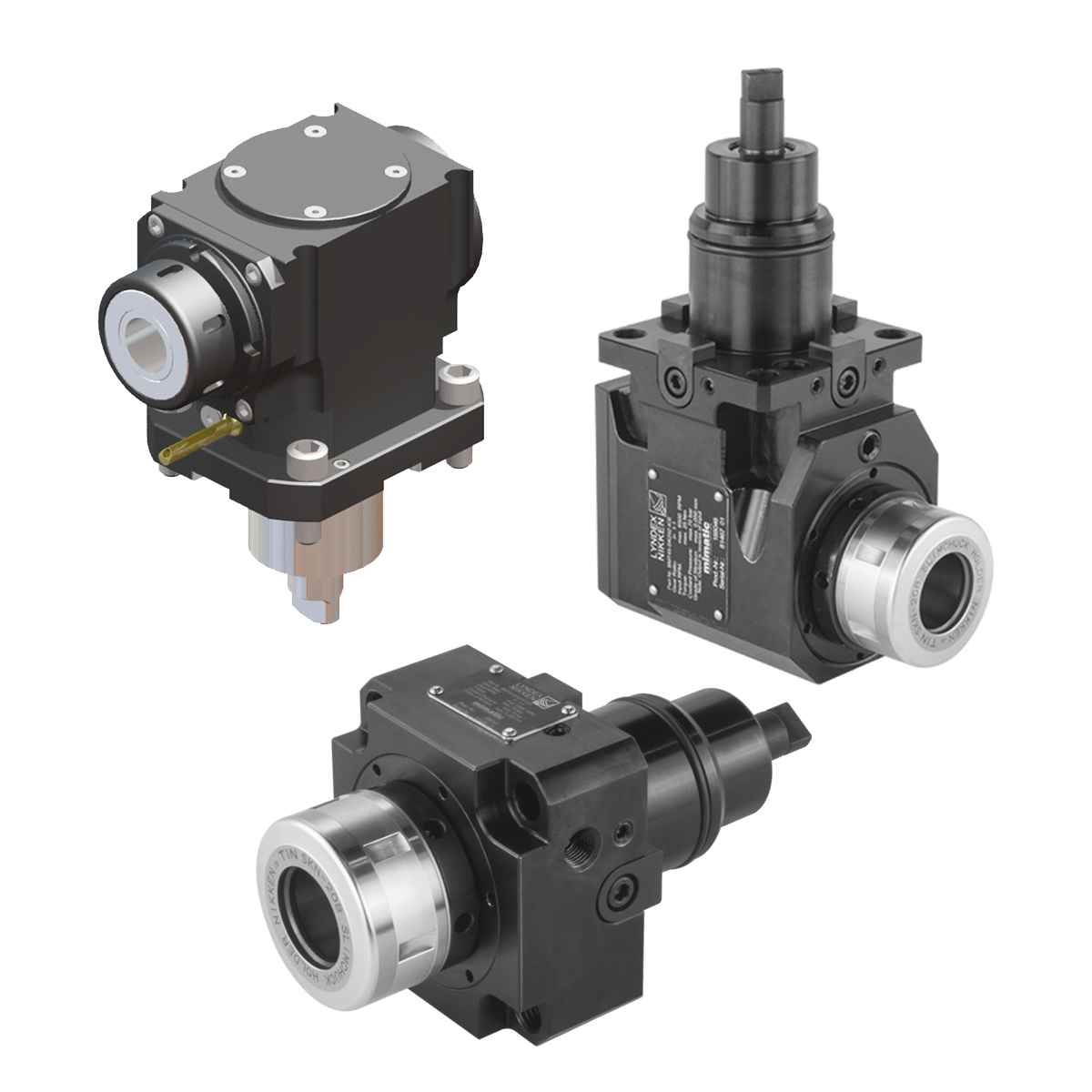

Quality Live Tools with the Lyndex-Nikken Advantage

Quality live tools are designed for machining the highest quality parts by providing these benefits:

- Nickel chrome molybdenum body for durability and resistance to wear and corrosion

- Ground features to ensure optimal concentricity

- ABEC 7 angular contact bearings for highest run-out precision

- Run-out guarantee of under 5-micron repeatability at collet nose

Gears, bearings, and seals are engineered to provide the highest accuracy, rigidity and stability to optimize machine performance and productivity.

Gears for Stability

- Hand-matched gears for minimal backlash

- Spiral bevel gears maximizes drive torque

- Optimal bearing placement for balanced torque stress

Protective Seals

Labyrinth seals with unique multi-barrier construction prevent contaminants from entering the main chamber

SK Live Tooling Provides Higher Gripping Force

Some common challenges manufacturers face with live tools is high runout or pulling out of cutting tools ruining a workpiece. SK live tools can solve these challenges due to higher gripping force, ability to machine with higher chip loads, and reduced cycle times.

Live tools can have an ICE (Internal Coolant + External Option) feature that allows internal coolant live tools to be ran dry continuously.

Watch the video to learn the difference between SK ICE live tooling from traditional SK live tooling:

There are three key benefits of using SK ICE live tooling instead of traditional live tooling:

Higher Gripping Force - You can machine with higher chip loads and reduce cycle time with better cutting conditions; additionally, eliminates over tightening that leads to collet damage and excessive runout while reducing end mill pullout and scrap parts.

Greater Rigidity, Precision, and Clearance - The longer and slimmer 8° taper SK collet allows for a smaller body diameter enabling working closer to the chuck that gives greater rigidity, precision, and clearance.

Run With or Without Coolant - SK ICE live tooling is designed to be run with or without coolant through the live tool, allowing them to be run dry without breaking. It is easy to change between coolant set ups and can be used in a variety of applications without changing out tooling - allowing for minimal downtime.

When comparing the results of SK live tools to ER live tools, SK live tools consistently outperform ER live tools. See the difference between machining with ER live tools versus SK live tools in this test cut demo video:

Bottom line is when using an ER32 Z axis or X axis live tools, the tool starts pulling out during machining or breaks. On the other hand, using the SK 20 Z axis or X axis live tools machining the same cut as the ER live tool - the SK live tool plows right through and completes the cut with no issues, no cutter pull out, and the tool does NOT break.

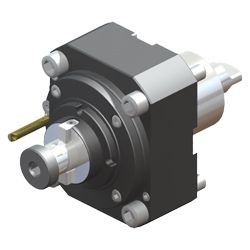

Live Tool Styles Engineered for Efficiency and Versatility

Live tools are available in many different styles as well as options for coolant through, adjustable, and multi-output. Live tools are offered for a multitude of machine builders. Additionally, custom-made live tools can be engineered for specific applications.

90 Degree |

Straight |

Adjustable |

Collet Chuck |

Shell Mill Holder |

Modular System |

Converting ICE Style Live Tooling from Internal to External Coolant

It's always best to consider the specific requirements of the machining operation and select the coolant delivery method that best suites the application.

In certain applications, converting internal coolant live tooling to external coolant can offer various benefits including improved chip evacuation, enhanced cooling and lubrication, reduced tool wear, increased machining speeds and feeds, and greater flexibility in coolant delivery.

- Improved Chip Evacuation: External coolant delivery can help facilitate better chip evacuation from the cutting zone. This is particularly beneficial when machining materials that tend to produce long, stringy chips, as the external coolant can help break them up and flush them away from the cutting area more effectively.

- Enhanced Cooling: External coolant can provide more efficient cooling to the cutting tool and workpiece, especially in high-speed machining applications or when machining heat-sensitive materials. By delivering coolant directly to the cutting zone from outside the tool, external coolant can help dissipate heat more effectively, prolonging tool life and reducing the risk of thermal damage to the workpiece.

- Reduced Tool Wear: External coolant can help reduce tool wear by providing lubrication and cooling directly to the cutting edges of the tool. This can result in longer tool life and improved machining performance, particularly in demanding applications or when machining abrasive materials.

- Increased Machining Speeds and Feeds: External coolant can enable higher machining speeds and feeds by effectively managing heat buildup and reducing the risk of tool overheating. This can lead to shorter cycle times and increased productivity without sacrificing machining quality or accuracy.

- Flexibility in Coolant Delivery: External coolant systems often offer greater flexibility in coolant delivery options, allowing for adjustable flow rates, spray patterns, and coolant types. This versatility can be advantageous in optimizing coolant application for specific machining tasks or materials.

See first-hand how you can convert ICE style live tooling from internal to external coolant in this quick tip video:

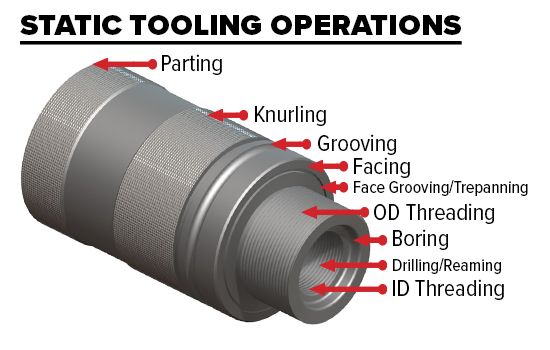

Static Tools Enable Stability & Precision

When the cutting tool is stationary and the part is spinning the tooling used is called static tooling. So, the cutting action is performed by the tool’s static position relative to the workpiece.

Typical turning operations that can be performed include ID threading, drilling, reaming, boring, OD threading, face grooving, trepanning, facing, grooving, knurling, and parting.

Static Tool Interfaces for CNC Turning Centers, Lathes, and Mill-Turn Machines

Static tools are available in 3 types of interfaces as well as options for coolant through, adjustable, and multi-output. Static tools are offered for a multitude of machine builders.

Static Tools - PSC Polygonal: As precisely defined per ISO 26623, the Polygon Shank Coupling (PSC) interface features a unique tapered polygon which serves as a main element in torque transmitting, centering, and clamping. With double contact on both face and taper, as well as great cross-sectional strength, this interface is unrivaled in terms of high clamping force and bending stiffness.

Static tools with PSC polygonal connections offer several advantages:

Precision: The polygonal connection provides a tight and accurate fit between the tool and the machine, minimizing tool runout and enhancing machining precision.

Stability: The secure connection ensures that the static tool remains stable during machining operations, reducing vibrations and improving surface finish on machined parts.

Compatibility: PSC polygonal connections are standardized, making them compatible with a wide range of CNC machining centers that support this type of interface.

Static Tools - Bolt Mount: Bolt-mounting refers to the method of attaching the static tools to the tool turret of the CNC machine. The tools are secured firmly in place using bolts or screws, ensuring stability during machining operations.

Static tools that are bolt-mounted offer several advantages:

Stability: The bolt-mounting method ensures that the static tools remain securely fixed in position, minimizing vibrations and enhancing machining accuracy.

Durability: The secure attachment provided by bolt-mounting helps prevent tool movement or deflection during machining, thereby increasing tool longevity.

Compatibility: Bolt-mounting static tools are compatible with a wide range of CNC machines that utilize turret-based systems. They can be easily installed and replaced as needed.

Static Tools - VDI (Verein Deutscher Ingenieure or Association of German Engineers): Traditional cutting tools that are mounted on the tool turret of a CNC machine using the VDI tooling interface standard. VDI is a standardized interface system predominantly used in Europe for tooling in CNC turning centers and lathe machines. Unlike live tools, static tools do NOT have rotational capabilities or the ability to perform additional operations beyond their fixed position.

Static tools within the VDI system offer several advantages:

Interchangeability: The VDI standard ensures interchangeability of tooling across different machines and manufacturers that adhere to the VDI standard. This allows for easy replacement and compatibility between various tools and machines.

Tool Repeatability: The precise design of VDI toolholders ensures repeatability in tool positioning, resulting in consistent machining accuracy.

Quick Tool Changes: The standardized interface facilitates rapid tool changes, reducing setup time and increasing machine productivity.

Static Tools - Turret Specific: Offered for a multitude of machine builders to maximize the capabilities of each CNC machine equipped with turrets, offering increased flexibility, efficiency, and productivity in machining operations.

Static Tool Styles Engineered for Stability & Precision

Static tools are available in many different styles as well as options for coolant through, adjustable, and multi-output. Static tools are offered for a multitude of machine builders.

Boring Bar |

Cut Off |

Collet Chuck |

ID Holder |

OD Holder |

Videos: Why Manufacturers Choose Lyndex-Nikken Live & Static Tools

Hear and see for yourself how Lyndex-Nikken quality live and static tools provide optimal machining solutions for: